Difference between revisions of "ENA Amplifier - Mounting and Installation"

From Zenitel Wiki

(→Grounding) |

m (Tag: Visual edit) |

||

| Line 1: | Line 1: | ||

{{A}} | {{A}} | ||

| − | This article describes the mounting and installation of the '''ENA2200''', '''ENA2400-AC''' | + | This article describes the mounting and installation of the '''ENA2200''', '''ENA2400-AC''' and '''ENA2400-DC''' amplifiers. |

| − | === Overview - Front === | + | ===Overview - Front=== |

[[File:ENA2200 Overview Front.PNG|left|ENA2200]] | [[File:ENA2200 Overview Front.PNG|left|ENA2200]] | ||

<br style="clear:both;" /> | <br style="clear:both;" /> | ||

{| border="1" | {| border="1" | ||

| − | | align="center" style="background:#ffd400;" width="50pt"| 1 || align="left" | + | | align="center" style="background:#ffd400;" width="50pt" |1|| align="left" |Mounting Flange|| align="left" |The mounting flanges are used to mount the unit in 19” equipment racks |

|- | |- | ||

| − | | align="center" style="background:#ffd400;" width="50pt"| 2 || align="left" | + | | align="center" style="background:#ffd400;" width="50pt" |2|| align="left" |Ventilation Inlets|| align="left" |The ventilation inlets should be kept free of obstacles and dust. Fans control the airflow based on internal temperature |

|- | |- | ||

| − | | align="center" style="background:#ffd400;" width="50pt"| 3 || align="left" | + | | align="center" style="background:#ffd400;" width="50pt" |3|| align="left" |Headphone Jack|| align="left" |The headphone connection can be used to listen to the different audio streams in the Amplifier. |

|- | |- | ||

| − | | align="center" style="background:#ffd400;" width="50pt"| 4 || align="left" | + | | align="center" style="background:#ffd400;" width="50pt" |4|| align="left" |Status Indicators|| align="left" |The status indicators are used to display the status of important parameters such as power supplies and faults |

|- | |- | ||

| − | | align="center" style="background:#ffd400;" width="50pt"| 5 || align="left" | + | | align="center" style="background:#ffd400;" width="50pt" |5|| align="left" |LCD Display|| align="left" |The LCD screen displays status and a graphical user interface |

|- | |- | ||

| − | | align="center" style="background:#ffd400;" width="50pt"| 6 || align="left" | + | | align="center" style="background:#ffd400;" width="50pt" |6|| align="left" |Control Knob|| align="left" |The control knob is used to select and execute menu items in the user interface. The knob can be rotated and pressed. |

|- | |- | ||

| − | | align="center" style="background:#ffd400;" width="50pt"| 7 || align="left" | + | | align="center" style="background:#ffd400;" width="50pt" |7|| align="left" |Integrated Handle|| align="left" |These integrated handles make it easy to maneuver the unit, without adding to the installation depth |

|- | |- | ||

| − | | align="center" style="background:#ffd400;" width="50pt"| 8 || align="left" | + | | align="center" style="background:#ffd400;" width="50pt" |8|| align="left" |Ventilation Inlets|| align="left" |The ventilation inlets should be kept free of obstacles and dust. Fans control the airflow based on internal temperature |

|- | |- | ||

| Line 28: | Line 28: | ||

----------- | ----------- | ||

| − | === Overview - Back === | + | ===Overview - Back=== |

[[File:ENA2200 Overview Back.PNG|left|ENA2200]] | [[File:ENA2200 Overview Back.PNG|left|ENA2200]] | ||

<br style="clear:both;" /> | <br style="clear:both;" /> | ||

{| border="1" | {| border="1" | ||

| − | | align="center" style="background:#ffd400;" width="50pt"| 1 || align="left" | + | | align="center" style="background:#ffd400;" width="50pt" |1|| align="left" |Ethernet Ports|| align="left" |Redundant Ethernet connections for audio and control data |

|- | |- | ||

| − | | align="center" style="background:#ffd400;" width="50pt"| 2 || align="left" | + | | align="center" style="background:#ffd400;" width="50pt" |2|| align="left" |Serial Console|| align="left" |Serial port connection for debugging and factory programming |

|- | |- | ||

| − | | align="center" style="background:#ffd400;" width="50pt"| 3 || align="left" | + | | align="center" style="background:#ffd400;" width="50pt" |3|| align="left" |Control Inputs|| align="left" |6 configurable control inputs. Each input is activated by closing the loop between the two terminals |

|- | |- | ||

| − | | align="center" style="background:#ffd400;" width="50pt"| 4 || align="left" | + | | align="center" style="background:#ffd400;" width="50pt" |4|| align="left" |Fault Relay Output|| align="left" |A switching relay (NO, NC & COM) kept in the active position between COM and NO as long as no faults are present in the device |

|- | |- | ||

| − | | align="center" style="background:#ffd400;" width="50pt"| 5 || align="left" | + | | align="center" style="background:#ffd400;" width="50pt" |5|| align="left" |Control Outputs|| align="left" |Six configurable control outputs. Each is made of a switching relay (NO, NC and COM) in parallel with a 24VDC signal. The 24VDC part of the control output can source max 200mA and has overcurrent protection |

|- | |- | ||

| − | | align="center" style="background:#ffd400;" width="50pt"| 6 || align="left" | + | | align="center" style="background:#ffd400;" width="50pt" |6|| align="left" |Audio Inputs|| align="left" |Microphone and line-in audio inputs for microphones or external audio sources |

|- | |- | ||

| − | | align="center" style="background:#ffd400;" width="50pt"| 7 || align="left" | + | | align="center" style="background:#ffd400;" width="50pt" |7|| align="left" |Speaker Outputs|| align="left" |100 and 70 volt outputs per channel. Each channel also has a low-power 8ohm output for single speakers. Each channel is equipped with inputs for connection to a hot-standby amplifier |

|- | |- | ||

| − | | align="center" style="background:#ffd400;" width="50pt"| 8 || align="left" | + | | align="center" style="background:#ffd400;" width="50pt" |8|| align="left" |Ground Connection|| align="left" |Ground connection for grounding of the unit. This is connected in parallel with the ground connection in the AC power inlet |

|- | |- | ||

| − | | align="center" style="background:#ffd400;" width="50pt"| 9 || align="left" | + | | align="center" style="background:#ffd400;" width="50pt" |9|| align="left" |DC Power Inlet|| align="left" |DC power inlet for 24 to 48 VDC (''Not available on the ENA2400-AC amplifier'') |

|- | |- | ||

| − | | align="center" style="background:#ffd400;" width="50pt"| 10 || align="left" | + | | align="center" style="background:#ffd400;" width="50pt" |10|| align="left" |AC Power Switch|| align="left" |Power switch for AC power. This switch will not turn off the system controller if DC backup is connected (''Not available on the ENA2400-DC amplifier'') |

|- | |- | ||

| − | | align="center" style="background:#ffd400;" width="50pt"| 11 || align="left" | + | | align="center" style="background:#ffd400;" width="50pt" |11|| align="left" |AC Power Inlet|| align="left" |AC power inlet for 110 to 230 VAC. The power inlet has a V-Lock mechanism for a secure connection (''Not available on the ENA2400-DC amplifier'') |

|- | |- | ||

|} | |} | ||

| Line 58: | Line 58: | ||

----------- | ----------- | ||

| − | === Placement and Stacking === | + | ===Placement and Stacking=== |

The amplifier is designed to deliver full power at ambient temperatures up to 55 °C. As long as the equipment rack is well ventilated, amplifiers can be stacked with no extra space between them. It is however recommended to add 1 HU between every group of 4 amplifiers. | The amplifier is designed to deliver full power at ambient temperatures up to 55 °C. As long as the equipment rack is well ventilated, amplifiers can be stacked with no extra space between them. It is however recommended to add 1 HU between every group of 4 amplifiers. | ||

| − | === Mounting === | + | ===Mounting=== |

The amplifier’s mechanical construction is rigid enough to be mounted using only the four holes in the mounting flange to secure it to the rack. It is however considered good practice to mount | The amplifier’s mechanical construction is rigid enough to be mounted using only the four holes in the mounting flange to secure it to the rack. It is however considered good practice to mount | ||

support rails if the system is installed in a mobile environment. | support rails if the system is installed in a mobile environment. | ||

| − | === Power Supply === | + | ===Power Supply=== |

The Amplifier shall be connected to the equipment rack’s primary and secondary (emergency) source of power. | The Amplifier shall be connected to the equipment rack’s primary and secondary (emergency) source of power. | ||

| Line 72: | Line 72: | ||

The requirements for the power rails are listed in the Technical Specifications for the amplifier. The cables used for the power shall be dimensioned accordingly to the voltage and current consumption of the amplifier. | The requirements for the power rails are listed in the Technical Specifications for the amplifier. The cables used for the power shall be dimensioned accordingly to the voltage and current consumption of the amplifier. | ||

| − | === Grounding === | + | ===Grounding=== |

It is always good practice to ground the cabinet of equipment installed in racks. This ensures safety and good EMC. If the unit is powered entirely through the DC power inlet, the ground connection is the only way to connect the Amplifier to ground. The ground connection of the Amplifier should be connected to the equipment rack’s ground strip using a ground wire of at least 0.75 mm² (AWG 19). | It is always good practice to ground the cabinet of equipment installed in racks. This ensures safety and good EMC. If the unit is powered entirely through the DC power inlet, the ground connection is the only way to connect the Amplifier to ground. The ground connection of the Amplifier should be connected to the equipment rack’s ground strip using a ground wire of at least 0.75 mm² (AWG 19). | ||

| Line 78: | Line 78: | ||

<br style="clear:both;" /> | <br style="clear:both;" /> | ||

| − | === Ethernet Connections === | + | ===Ethernet Connections=== |

The Amplifier is connected to the network using one of the two Ethernet ports. | The Amplifier is connected to the network using one of the two Ethernet ports. | ||

| − | === Fault Relay === | + | ===Fault Relay=== |

The Amplifier’s fault relay will trigger whenever a fault occurs in the amplifier. This relay is actively kept closed by the Amplifier so it will trigger even if the entire amplifier loses power. The connection to external equipment should be made according to the external equipment’s requirements. When no faults are present in the amplifier, an electrical connection is established between the COM and NO terminals of the fault relay. When a fault is detected, or the amplifier loses power, this connection is removed and a connection between COM and NC is established. | The Amplifier’s fault relay will trigger whenever a fault occurs in the amplifier. This relay is actively kept closed by the Amplifier so it will trigger even if the entire amplifier loses power. The connection to external equipment should be made according to the external equipment’s requirements. When no faults are present in the amplifier, an electrical connection is established between the COM and NO terminals of the fault relay. When a fault is detected, or the amplifier loses power, this connection is removed and a connection between COM and NC is established. | ||

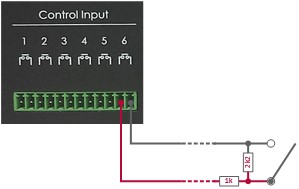

| − | === Control Inputs === | + | ===Control Inputs=== |

There are 6 inputs available. The inputs can be used in a convensional way, or they can be monitorted. | There are 6 inputs available. The inputs can be used in a convensional way, or they can be monitorted. | ||

[[File:Control_Inputs_5.jpg|thumb|left|700px|Control Input - Convensional use]] | [[File:Control_Inputs_5.jpg|thumb|left|700px|Control Input - Convensional use]] | ||

<br style="clear:both;" /> | <br style="clear:both;" /> | ||

| − | * Conventional inputs have two states: | + | |

| − | ** Contact is '''Open''' | + | *Conventional inputs have two states: |

| − | ** Contact is '''Closed''' | + | **Contact is '''Open''' |

| + | **Contact is '''Closed''' | ||

Monitoring is done by connecting two resistors as close as possible to the external switch/relay, one in series and one in parallel. | Monitoring is done by connecting two resistors as close as possible to the external switch/relay, one in series and one in parallel. | ||

| Line 99: | Line 100: | ||

Monitored Inputs have four states: | Monitored Inputs have four states: | ||

| − | * Contact is Open | + | |

| − | * Contact is Closed | + | *Contact is Open |

| − | * Short circuit (error) | + | *Contact is Closed |

| − | * Open circuit (error) | + | *Short circuit (error) |

| + | *Open circuit (error) | ||

Monitoring of inputs must be enabled in the web interface: [[ENA_Configuration_-_AlphaCom_mode#RCO.2FRCI_Config|Amplifier Settings > RCO/RCI Config > RCIs]] section. | Monitoring of inputs must be enabled in the web interface: [[ENA_Configuration_-_AlphaCom_mode#RCO.2FRCI_Config|Amplifier Settings > RCO/RCI Config > RCIs]] section. | ||

| − | === Control Outputs === | + | ===Control Outputs=== |

There are 6 NO/NC relays and 24V DC outputs. | There are 6 NO/NC relays and 24V DC outputs. | ||

Relay Outputs: | Relay Outputs: | ||

| − | * Max 24 VDC, 60 W | + | |

| − | * Max 250 VAC, 125 VA | + | *Max 24 VDC, 60 W |

| + | *Max 250 VAC, 125 VA | ||

| + | |||

24 VDC Outputs: | 24 VDC Outputs: | ||

| − | * 24 VDC, ±10%, 200 mA | + | |

| + | *24 VDC, ±10%, 200 mA | ||

Cable diameter used is max 1 mm2 flexible. | Cable diameter used is max 1 mm2 flexible. | ||

| − | === Audio Inputs === | + | ===Audio Inputs=== |

The two audio inputs on the Amplifier can be used for background music, external alarms or local microphone. The audio inputs should be routed to terminal blocks in the equipment rack or local audio sources. | The two audio inputs on the Amplifier can be used for background music, external alarms or local microphone. The audio inputs should be routed to terminal blocks in the equipment rack or local audio sources. | ||

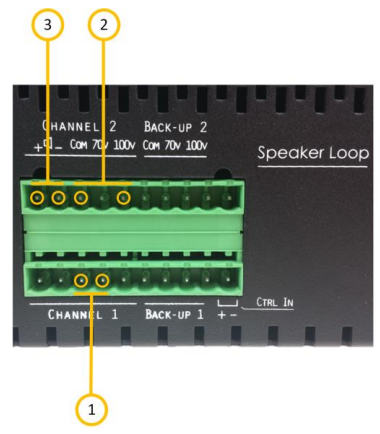

| − | === Loudspeaker Connections === | + | ===Loudspeaker Connections=== |

The Amplifier has three different options for loudspeaker connections: 8Ω, 70 volts and 100 volts. The 8Ω output is only intended for local monitoring of audio, and the power is therefore limited | The Amplifier has three different options for loudspeaker connections: 8Ω, 70 volts and 100 volts. The 8Ω output is only intended for local monitoring of audio, and the power is therefore limited | ||

compared to the 70 and 100 volt lines. | compared to the 70 and 100 volt lines. | ||

| Line 126: | Line 131: | ||

<br style="clear:both;" /> | <br style="clear:both;" /> | ||

{| border="1" | {| border="1" | ||

| − | | align="center" style="background:#ffd400;" width="50pt"| 1 || align="left" | + | | align="center" style="background:#ffd400;" width="50pt" |1|| align="left" |70 volt connection |

|- | |- | ||

| − | | align="center" style="background:#ffd400;" width="50pt"| 2 || align="left" | + | | align="center" style="background:#ffd400;" width="50pt" |2|| align="left" |100 volt connection |

|- | |- | ||

| − | | align="center" style="background:#ffd400;" width="50pt"| 3 || align="left" | + | | align="center" style="background:#ffd400;" width="50pt" |3|| align="left" |8Ω connection |

|- | |- | ||

|} | |} | ||

| Line 136: | Line 141: | ||

The loudspeaker outputs from the amplifier should be routed to terminal blocks in the equipment rack according to system requirements. | The loudspeaker outputs from the amplifier should be routed to terminal blocks in the equipment rack according to system requirements. | ||

| − | |||

| − | |||

| − | |||

[[Category: Public Address - Features and configuration]] | [[Category: Public Address - Features and configuration]] | ||

Revision as of 13:21, 4 March 2020

This article describes the mounting and installation of the ENA2200, ENA2400-AC and ENA2400-DC amplifiers.

Contents

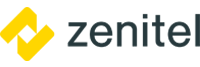

Overview - Front

| 1 | Mounting Flange | The mounting flanges are used to mount the unit in 19” equipment racks |

| 2 | Ventilation Inlets | The ventilation inlets should be kept free of obstacles and dust. Fans control the airflow based on internal temperature |

| 3 | Headphone Jack | The headphone connection can be used to listen to the different audio streams in the Amplifier. |

| 4 | Status Indicators | The status indicators are used to display the status of important parameters such as power supplies and faults |

| 5 | LCD Display | The LCD screen displays status and a graphical user interface |

| 6 | Control Knob | The control knob is used to select and execute menu items in the user interface. The knob can be rotated and pressed. |

| 7 | Integrated Handle | These integrated handles make it easy to maneuver the unit, without adding to the installation depth |

| 8 | Ventilation Inlets | The ventilation inlets should be kept free of obstacles and dust. Fans control the airflow based on internal temperature |

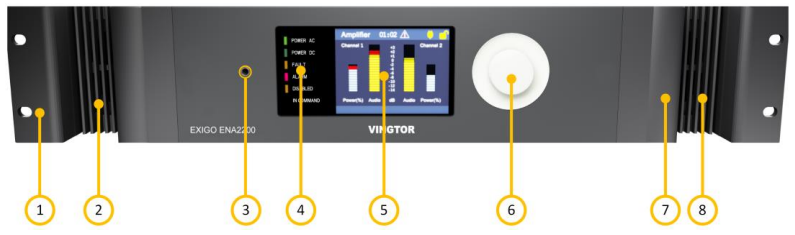

Overview - Back

| 1 | Ethernet Ports | Redundant Ethernet connections for audio and control data |

| 2 | Serial Console | Serial port connection for debugging and factory programming |

| 3 | Control Inputs | 6 configurable control inputs. Each input is activated by closing the loop between the two terminals |

| 4 | Fault Relay Output | A switching relay (NO, NC & COM) kept in the active position between COM and NO as long as no faults are present in the device |

| 5 | Control Outputs | Six configurable control outputs. Each is made of a switching relay (NO, NC and COM) in parallel with a 24VDC signal. The 24VDC part of the control output can source max 200mA and has overcurrent protection |

| 6 | Audio Inputs | Microphone and line-in audio inputs for microphones or external audio sources |

| 7 | Speaker Outputs | 100 and 70 volt outputs per channel. Each channel also has a low-power 8ohm output for single speakers. Each channel is equipped with inputs for connection to a hot-standby amplifier |

| 8 | Ground Connection | Ground connection for grounding of the unit. This is connected in parallel with the ground connection in the AC power inlet |

| 9 | DC Power Inlet | DC power inlet for 24 to 48 VDC (Not available on the ENA2400-AC amplifier) |

| 10 | AC Power Switch | Power switch for AC power. This switch will not turn off the system controller if DC backup is connected (Not available on the ENA2400-DC amplifier) |

| 11 | AC Power Inlet | AC power inlet for 110 to 230 VAC. The power inlet has a V-Lock mechanism for a secure connection (Not available on the ENA2400-DC amplifier) |

Placement and Stacking

The amplifier is designed to deliver full power at ambient temperatures up to 55 °C. As long as the equipment rack is well ventilated, amplifiers can be stacked with no extra space between them. It is however recommended to add 1 HU between every group of 4 amplifiers.

Mounting

The amplifier’s mechanical construction is rigid enough to be mounted using only the four holes in the mounting flange to secure it to the rack. It is however considered good practice to mount support rails if the system is installed in a mobile environment.

Power Supply

The Amplifier shall be connected to the equipment rack’s primary and secondary (emergency) source of power.

|

The power input(s) are equipped with a lock, preventing the plug from falling out. Make sure that the plug is properly inserted, and that the lock is engaged |

The requirements for the power rails are listed in the Technical Specifications for the amplifier. The cables used for the power shall be dimensioned accordingly to the voltage and current consumption of the amplifier.

Grounding

It is always good practice to ground the cabinet of equipment installed in racks. This ensures safety and good EMC. If the unit is powered entirely through the DC power inlet, the ground connection is the only way to connect the Amplifier to ground. The ground connection of the Amplifier should be connected to the equipment rack’s ground strip using a ground wire of at least 0.75 mm² (AWG 19).

|

If the Amplifier isn’t connected to ground, it will not be able to detect ground faults or short-circuits to ground |

Ethernet Connections

The Amplifier is connected to the network using one of the two Ethernet ports.

Fault Relay

The Amplifier’s fault relay will trigger whenever a fault occurs in the amplifier. This relay is actively kept closed by the Amplifier so it will trigger even if the entire amplifier loses power. The connection to external equipment should be made according to the external equipment’s requirements. When no faults are present in the amplifier, an electrical connection is established between the COM and NO terminals of the fault relay. When a fault is detected, or the amplifier loses power, this connection is removed and a connection between COM and NC is established.

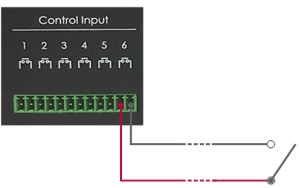

Control Inputs

There are 6 inputs available. The inputs can be used in a convensional way, or they can be monitorted.

- Conventional inputs have two states:

- Contact is Open

- Contact is Closed

Monitoring is done by connecting two resistors as close as possible to the external switch/relay, one in series and one in parallel.

The resistor connected in series with the external switch/relay shall have a value of 1 kΩ, while the resistor connected in parallel shall be 2.2 kΩ.

Monitored Inputs have four states:

- Contact is Open

- Contact is Closed

- Short circuit (error)

- Open circuit (error)

Monitoring of inputs must be enabled in the web interface: Amplifier Settings > RCO/RCI Config > RCIs section.

Control Outputs

There are 6 NO/NC relays and 24V DC outputs.

Relay Outputs:

- Max 24 VDC, 60 W

- Max 250 VAC, 125 VA

24 VDC Outputs:

- 24 VDC, ±10%, 200 mA

Cable diameter used is max 1 mm2 flexible.

Audio Inputs

The two audio inputs on the Amplifier can be used for background music, external alarms or local microphone. The audio inputs should be routed to terminal blocks in the equipment rack or local audio sources.

Loudspeaker Connections

The Amplifier has three different options for loudspeaker connections: 8Ω, 70 volts and 100 volts. The 8Ω output is only intended for local monitoring of audio, and the power is therefore limited compared to the 70 and 100 volt lines.

| 1 | 70 volt connection |

| 2 | 100 volt connection |

| 3 | 8Ω connection |

The loudspeaker outputs from the amplifier should be routed to terminal blocks in the equipment rack according to system requirements.